KEY FACTS

ZERO-ACCIDENT SAFETY, HIGH-PERFORMANCE RELIABILITY

Delivering trusted excellence with uncompromising safety standards while achieving vastly growing contract volumes year after year

0

Accidents in the last five years including 2025 @ around a growing average of around

18000+

contracts per year.

EXTENSIVE CROSS-INDUSTRY EXPERIENCE

40+ YEARS

Leveraging four decades of pioneering innovation and technological advancement, we stand at the forefront of delivering advanced heavy lifting and transportation solutions tailored for the evolving heavy industries segments.

INNOVATION-DRIVEN EXCELLENCE, MEASURABLE IMPACT

Empowering growth with certified quality, digital intelligence, and future-ready talent

Certification in accordance to ISO 9001:2015, SCC** and SCCP 100 %

Recurring customers per year 85 %

Of our clients’ contracts also procure our engineering services per year. 78 %

Of our colleagues are younger than 50 years. Our average age is 43, since 2017 we decreased our age by 11%. 76 %

Of our administrative workforce has completed a university degree. 50 %

ENGINEERING PRECISION, DIGITAL INTELLIGENCE, SEAMLESS EXECUTION

Fahrenholz, F360, and DETRACE - powering the future of heavy lifting and transport

Together, our three brands deliver an integrated ecosystem: Fahrenholz for execution excellence, F360 for smart engineering, and DETRACE for digital transparency. The result: safer, faster, and more cost-efficient projects that set new standards across industries worldwide.

OUR INDUSTRIES

Elevating global industries with innovative, digitalized heavy lifting and transport solutions

We empower global industries with integrated heavy lifting, precision transport, and digital engineering excellence. From power generation and process plants to minerals, metals, ports, offshore, manufacturing, aviation, and infrastructure, our solutions deliver safety, efficiency, and cost-optimization. Leveraging F360 smart simulations, OSS turnkey execution, and DETRACE digital transparency, we minimize downtime, accelerate project delivery, and ensure compliance. With a client-first mindset, certified expertise, and future-ready innovation, we set new benchmarks in performance, sustainability, and reliability across capital-intensive sectors.

POWER GENERATION

We deliver innovative heavy lifting and transport solutions that accelerate time-to-grid. With digital engineering, OSS integration, and turnkey execution, we ensure compliance, sustainability, and efficiency, empowering future-ready energy infrastructure across the evolving global power sector.

PROCESS PLANTS & BUILDING MATERIALS

We streamline complex industrial projects and turnarounds with OSS+ digital logistics, F360 planning, and advanced safety strategies. Our approach ensures operational continuity, minimized downtime, and optimized costs, setting new standards in high-risk, capital-intensive process industries.

MINERALS & METALS

We drive efficiency and productivity in the mining and steel sectors through advanced engineering, precision logistics, and integrated execution. Our solutions reduce downtime, mitigate risks, and maximize performance in the world’s most CAPEX-heavy, repair-intensive industrial environments.

PORTS, SHIPYARDS & OFFSHORE

We enable safe, efficient, and digitally optimized lifting and logistics for maritime industries. With integrated OSS solutions, advanced engineering, and certified teams, we secure operational excellence, resilience, and agility, shaping the future of ports, shipyards, and offshore operations.

MANUFACTURING, AUTOMOTIVE & AEROSPACE

We ensure seamless production continuity with digitalized lifting, transport, and logistics. Combining precision engineering, operational excellence, and agile execution, we empower global manufacturing, mobility, and aerospace industries to achieve cost efficiency, innovation, and zero-disruption performance.

INFRASTRUCTURE PROJECTS

We transform critical infrastructure development with data-driven lifting strategies, F360 planning, and OSS integration. Our innovative solutions guarantee budget certainty, accelerated schedules, and sustainable resilience, driving the successful delivery of tomorrow’s bridges, highways, and urban megastructures.

CAPABILITIES: FAHRENHOLZ INTEGRATED SERVICES

01

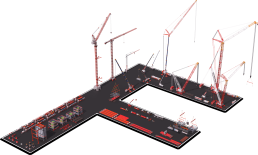

HEAVY LIFTING SOLUTIONS

Deploying a cutting-edge mobile crane fleet (all-terrain, rough-terrain, crawler), Fahrenholz guarantees high-precision lifting across fast-paced, high-stakes projects. With brands like Liebherr, Demag, Tadano Faun, and Grove, our fleet—average age just four years—ensures peak performance in complex lifting scenarios. Supported by F360 lift planning and full-service contract lifting, we offer safe, efficient, and digitally engineered heavy lift execution, tailored to mission-critical industries where downtime is not an option.

02

SPMT SOLUTIONS

Our Self-Propelled Modular Transporters (SPMTs)—Scheuerle, Goldhofer, and Sefiro—deliver digitally steered, hydraulically leveled power for 1,000+ ton components. With 45t axle line loads, multiway steering, and synchronized operations, SPMTs redefine mobility in tight industrial or urban spaces. We enable zero-error positioning of the heaviest assets, creating seamless integration into megaproject workflows and accelerating schedules through smart modularization and real-time precision handling.

03

INSTALLATION SERVICES

Specializing in hydraulic lifting, skidding, strand jacks, and gantries, Fahrenholz leads in ultra-heavy component positioning. Our benchmark hydraulic power solutions ensure millimeter accuracy even under extreme loads. From stacks to steel girders, our installation engineering integrates jacking and sliding technologies for safe, accelerated, and cost-optimized project delivery. Combining digital modeling with onsite execution excellence, we unlock risk-free heavy installations for refineries, power plants, shipyards, and beyond.

04

HEAVY HAULAGE & TRANSPORT

With 50+ semi, hydraulic, and modular trailers, our road transport division provides agile, responsive mobility for oversized and overweight cargos up to 300 tons. Equipped with extendable mega trailers, lowbeds, and flatbeds, we ensure logistics precision on every route. By leveraging digital tracking (DETrace) and advanced routing intelligence, we minimize delays, optimize safety, and maximize payload reliability, transforming road transport into a high-tech backbone of industrial megaprojects.

05

SUPPLIES

We provide end-to-end load management assets—steel beams, hardwood mats, crane pads, and concrete/steel blocks—for optimal ground stability and load distribution. Available on-site, off-site, or from dedicated depots, our supplies secure operational safety and efficiency in every heavy-lift and transport scenario. With meticulously maintained logistics infrastructure, we ensure that every project phase is supported with robust, compliant, and instantly deployable materials—critical for high-reliability industrial operations.

06

HR SERVICES

Behind every crane and trailer stands a specialized workforce of coordinators, riggers, lift supervisors, SPMT operators, and data managers. Our HR solutions offer skilled assembly teams, project engineers, and multilingual supervisors, all certified to DGUV standards. We deliver seamless human integration into high-risk sites, combining technical expertise, safety culture, and execution discipline. With flexible staffing solutions, we empower clients to scale execution teams rapidly, ensuring projects remain on track, safe, and profitable.

07

F360 ENGINEERING AND CONSULTING SERVICES

Our F360 digital engineering module sets the industry benchmark for end-to-end pre-simulation of heavy lifting and logistics. Covering feasibility, testing, VR modeling, and execution planning, it enables risk-free decision-making and stakeholder engagement through photorealistic 4D animations. With 50+ major projects annually, we optimize crane operations, rigging, and transport concepts—reducing surprises and compressing schedules. F360 delivers data-driven insights that cut costs, enhance safety, and boost time-to-operation in megaproject environments.

08

FAHRENHOLZ OSS

Our One-Stop-Shop (OSS) integrates all lifting, transport, rigging, and engineering services into a single streamlined offering. From conceptual planning to commissioning, OSS minimizes interfaces, reduces risks of operational setbacks, and creates synergies across execution phases. By bundling services, we deliver faster schedules, lower logistics costs, and higher productivity. Clients gain a single trusted partner orchestrating every facet of their heavy-lift and transport ecosystem.

09

FAHRENHOLZ OSS+

OSS+ adds digital intelligence via DETrace real-time monitoring, enabling 24/7 equipment tracking, performance dashboards, and predictive logistics insights. By combining planning, frontloading, consulting, and claim management with digital transparency, OSS+ transforms traditional projects into data-driven ecosystems. Clients benefit from instant visibility, proactive decision-making, and reduced downtime, unlocking next-generation heavy-lift logistics where physical execution meets digital transformation—ensuring compliance, cost control, and execution precision at scale

OUTSTANDING TECHNOLOGIES

Increased turnover from the use of our consumer applications

44

To date, we have worked in 44 nations on four continents.

9

Languages are the basis of our communication: Albanian, Bosnian, Croatian, English, French, German, Italian, Russian & Spanish

200%

We more than doubled our number of employees since 2017

18%

Since 2017, our employee tenure has risen by 18%, with an average duration of 5.6years across the entire workforce and 9.8 years for overhead and office roles.

F360 empowers early-stage risk and bottleneck identification through precise simulations and seamless BIM data integration. This enables reliable achievement of defined project targets. Continuously updated data and execution-driven planning significantly reduce the need for scope expansions during installation. As a result, commercial risks caused by inaccurate budget or schedule assumptions are effectively mitigated.

OPTIMIZING PROJECT TARGETS WITH

When it comes to absolute precision, unwavering reliability, and groundbreaking technological innovation in the world of cranes and transport, we draw on nearly four decades of expertise and a compelling track record of success. Today, our core competency revolves around the development of cutting-edge, highly efficient crane, transport, and assembly solutions, meticulously engineered to meet the unique requirements of our most demanding client projects. Our state-of-the-art fleet of advanced machinery is complemented by a dedicated team of experts, whose technical mastery ensures that we not only meet the industry's most rigorous demands but exceed them. Through meticulously planned, tailor-made crane, transport, and installation concepts, we drive even greater efficiency in execution. At Fahrenholz F360, we are redefining crane, transport, and assembly engineering by delivering high-end solutions that continuously push the boundaries of what is possible. Precision, innovation, and cutting-edge technology lie at the core of everything we do, empowering us to tackle the most complex heavy industry challenges with unrivaled expertise and commitment. Fueled by a relentless drive for perfection, we embrace challenges with ingenuity, turning complexity into opportunity. For us, engineering is where imagination meets technology, where innovation knows no limits, and where every project stands as a testament to our unwavering commitment to quality, precision, and excellence. Through our four-dimensional engineering approach and scientific analysis of assembly processes, we enhance not only operational safety and planning accuracy but also identify optimization potential and key interfaces at an early stage. By simplifying complexity, our structured solutions allow for highly accurate data-driven budget planning well before execution, providing clients with unmatched reliability and cost transparency.

F360 ENGINEERING AND CONSULTING SERVICES

At Fahrenholz, our F360 Engineering Services provide data-driven, precision-engineered solutions for complex lifting, transport, and assembly projects. Our expertise spans feasibility analysis, risk mitigation, and cost optimization, ensuring streamlined execution and maximum project efficiency. We have a portfolio of over 2,000 different models for crane, transport and assembly technology, ensuring tailor-made solutions for even the most complex lifting, transport, and installation challenges.

DATA-DRIVEN AUTOMATION FOR PRECISION ENGINEERING

From this, we develop comprehensive programs that provide all stakeholders with data-driven, quantitatively objective, and fully automated results and forecasts, ensuring maximum efficiency and accuracy in project execution.

ADVANTAGES OF F360

F360 Engineering integrates advanced modeling, feasibility assessments, crane studies, simulations, and animations, along with potential analyses and claims management support. This enables us to streamline the entire lifecycle of large-scale plant construction—from basic engineering and budgeting to decision-making, execution, and commissioning—with precision-driven expertise. We leverage industry-leading engineering capabilities, continuously enhanced through in-house expertise and strategic skill development. Our approach challenges traditional and conventional methodologies, exploring innovative solutions to reduce complexity, maximize economic benefits, and uphold the highest safety standards in volatile project environments.If it cannot be measured, it cannot be achieved. A core element of our engineering process is data-driven decision-making, ensuring that all outcomes are technically and quantitatively validated. By utilizing BIM data, real-world dimensions, and our continuously updated equipment database, our project simulations eliminate uncertainty and outdated assumptions. This results in highly precise execution strategies, realistic budgeting, and reliable scheduling, ensuring that deadlines and cost frameworks are met or exceeded.